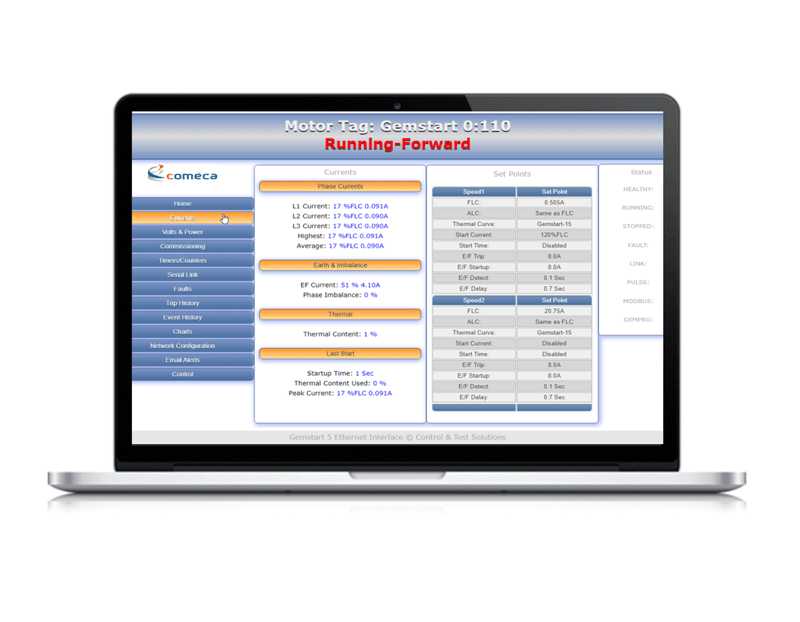

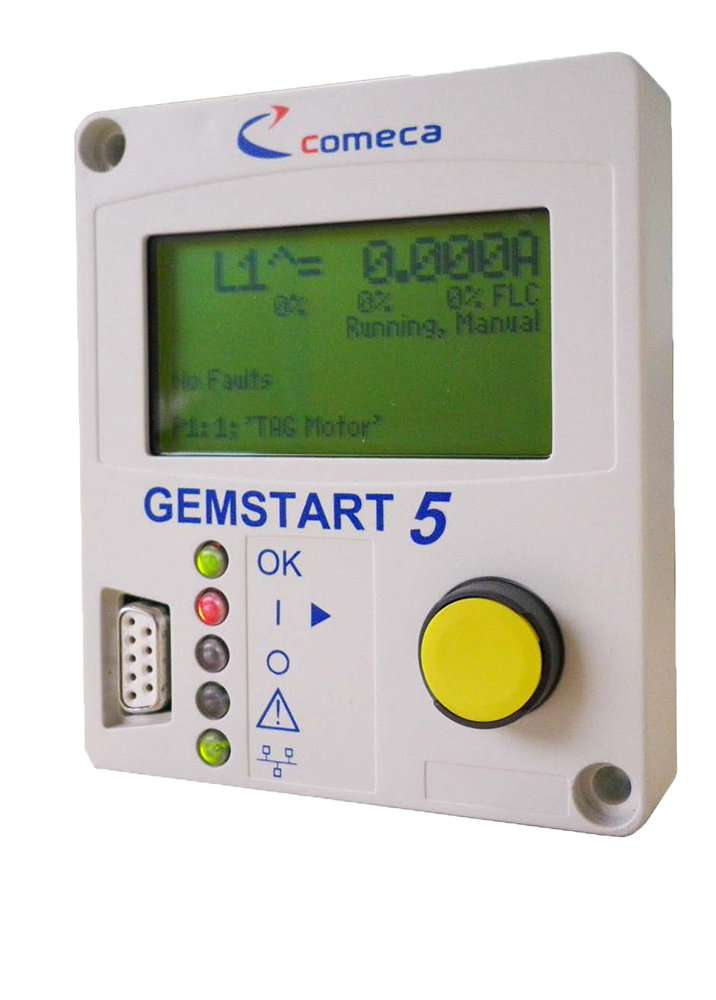

The service provided by digital protection is to ensure continuity of service and production by giving complete and early information to the electrician maintainer and more synthetic information to the process operator.

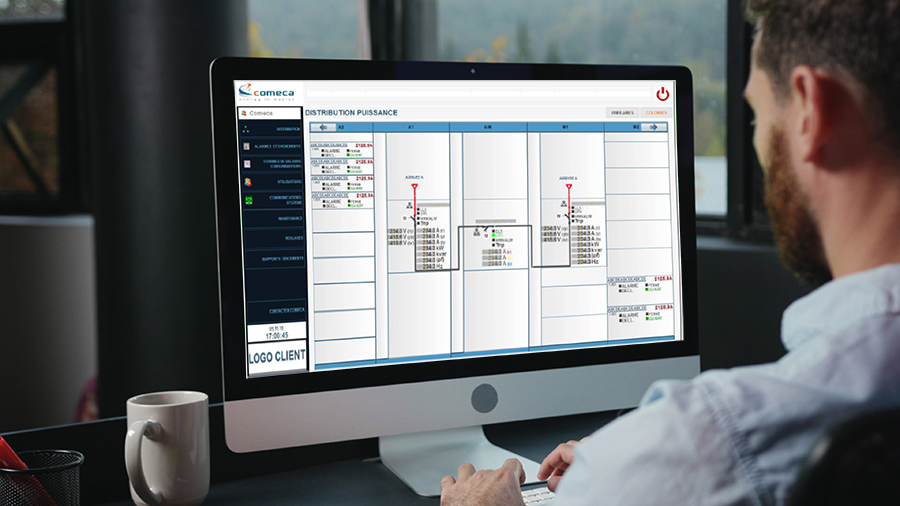

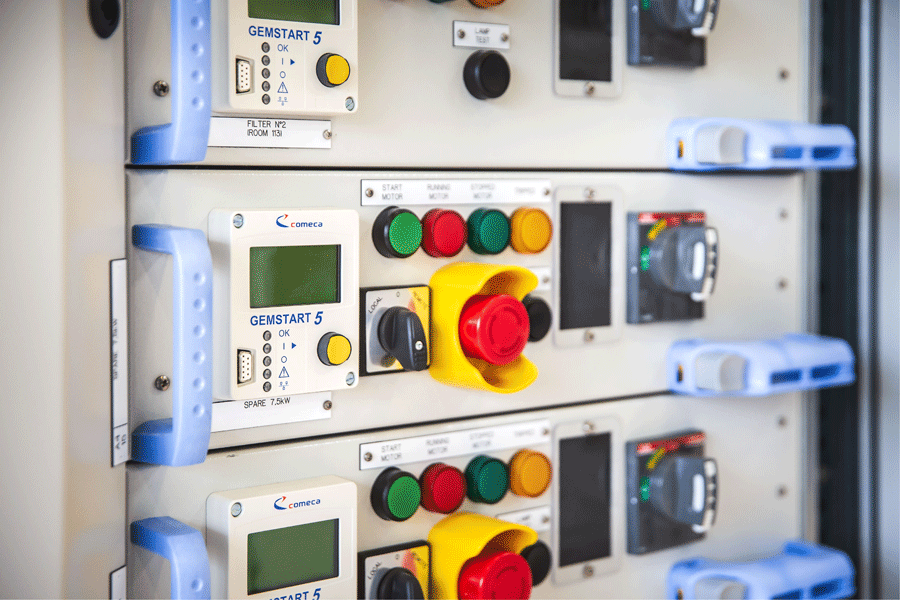

The electrician can display on his electrical switchboard or on his terminal all the information, alarms, status, measurements and history that are useful to him. He can choose to "overload" himself with information to improve his preventive or predictive approach.

For process control, the information is more synthetic because the most important information is the availability of the engine when running or stopped, as well as its percentage of load. An additional indication may be that the motor is "at risk", i.e. that it has left its reliability zone although it is still perfectly functional. This indication alone, which may include a number of alarms, allows the process to be moderated or a back-up motor to be considered.